OptiFuel’s innovative modular locomotive systems facilitate rapid and efficient production, retrofits, and maintenance – empowering railroads to customize locomotives, efficiently trial and integrate new technologies and fuels, and easily and quickly swap power modules as needed.

Beaufort, SC – (BUSINESS WIRE) – OptiFuel Systems announced today a new line of Total-ZeroTM Diesel Hybrid and Total-ZeroTM Diesel-RNG Dual Fuel Hybrid Series Locomotives. Production and delivery expected in 2026 and either model can be retrofitted to any existing switcher or line haul platform.

Engineered to deliver best-in-class continuous and peak power, fuel efficiency, and operating uptime, these locomotives empower railroads to comply with emissions standards while also achieving significant gains in reliability, safety, and profitability. This breakthrough enables railroads to continue utilizing diesel as the primary fuel, significantly reducing barriers and transition risks associated with adopting zero emission technologies by minimizing high infrastructure costs and eliminating key operational constraints, such as the need for a tender car.

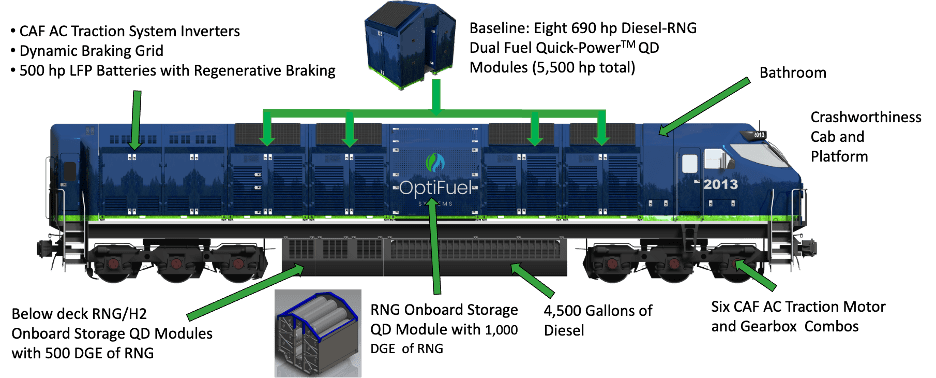

Total-Zero™ Diesel-RNG Dual Fuel Hybrid Series

The dual fuel series integrates the capability for the power system to run on up to 33% renewable natural gas (RNG), providing greenhouse gas (GHG) elimination in addition to elimination of NOx and PM. Railroads can adjust GHG emissions down to zero in real-time by simply modifying the blend of RNG and diesel. This flexibility supports Class 1 railroads in meeting science-based target initiative (SBTi) milestones for GHG reductions. Expected emissions for the Dual Fuel Series are:

- NOx: <0.035 to >0.02 g/bhp-hr

- PM: <0.005 g/bhp-hr

- GHG: Zero (0) gCO2eq/MJ

Note that these criteria emissions are 88% cleaner than the original proposed CARB Tier 5 standards.

The Key Benefits of OptiFuel Total-ZeroTM Diesel Series Locomotives are:

- Capable of traveling 1,500 miles—from the Ports of Los Angeles or Long Beach to Chicago—without refueling or the need for a tender

- Up to 20% reduction in diesel use compared to Tier 4 Diesel

- Redundant power for extreme high availability and reliability to guarantee tractive power – 5500 hp IC Diesel and 500 hp Battery Power for a total peak power of 6000 hp

- AC Traction with Regenerative Braking: Maintains full tractive effort even with the loss of one traction motor

- 30-year locomotive lifespan with flexibility to simply swap out modules for upgrades and transitions to future technologies or alternative fuels

- Expected 95% operating uptime, surpassing the industry average of 81% for diesel locomotives

- On-track 1-hour engine module replacement, minimizing disruptions and out-of-order assets

- Lower lifetime operating and maintenance expense

No Fuel Tender Required

“The new Diesel-RNG dual fuel system is groundbreaking because it eliminates the need for a fuel tender in zero emission line haul operations. The use of any type of tender for line haul operations is higher risk, incurs significant cost to build and test, and will be expensive to refuel and operate. Moreover, they will reduce overall safety to the public. We have closely monitored emerging technologies, in particular advanced engine technologies, and this solution enables railroads to continue operating predominantly on diesel while achieving zero emissions.” – Scott Myers, CEO OptiFuel Systems

Efficient Integration of RNG Dispensers to Diesel Islands at Existing Railroad Refueling Stations Across the Class 1 Network

“The efficiency of dual fuel extends beyond eliminating the tender car. Each RNG dispenser can refuel 2,500 diesel gallon equivalents (DGE) of RNG into line haul locomotives every 30 minutes, enabling the refueling of 48 locomotives per site each day. At a cost of about $20 million per station, we can establish the necessary refueling infrastructure with off-the-shelf equipment for approximately $1.2 billion, which is a fraction of the expense associated with transitioning to hydrogen, battery-electric, or catenary systems.” – Scott Myers

Technology and Operational Tested and Proven: Focus on Reliability, Safety Testing, FRA Concurrence, and Preproduction from 2025 to 2028

OptiFuel has a proven track record in alternative fuels and dual fuel systems. Founder Scott Myers led the development of one of the earliest diesel-CNG dual fuel power systems for Class 8 trucks, and the first for rail applications. The company has successfully integrated both RNG engines and hydrogen fuel cells into locomotive power systems, becoming the first locomotive supplier to obtain FRA concurrence for a CNG/RNG storage system onboard a freight locomotive. Additionally, OptiFuel constructed the world’s first CNG/RNG fuel station for locomotives, seamlessly integrating pumps into the existing diesel refueling infrastructure at the Indiana Harbor Belt Railroad (watch refueling video here). This innovation allows the railroad to refuel dual fuel locomotives with both diesel and CNG simultaneously.

OptiFuel’s modular locomotive power and fuel storage systems facilitate highly efficient component integrations, testing, optimization, and adaptation, effectively removing the constraints that have historically hindered technological innovation and new market entrants in the rail sector. This nimbleness enables OptiFuel to combine off-the-shelf components with proprietary technologies, allowing the adoption of the newer, safer, and more reliable technologies that the rail industry needs today.

About OptiFuel Systems LLC:

OptiFuel Systems is a solution provider designing and manufacturing Total-Zero™ emission products and services in the hard-to-abate transportation and industrial markets, specifically in rail, marine and power generation. OptiFuel works as a systems integrator with strategic partners to engineer innovative technology that is low-risk and modular with flexible fuel options including diesel, renewable natural gas (RNG) and hydrogen fuels.