BEAUFORT, SC, February 14, 2020 – OptiFuel Systems, LLC, recently secured U.S. EPA, Tier 4 Rail Certification for the first ever rail internal combustion engine to emit 0.00 g/bhp-hr NOx and PM. This revolutionary breakthrough for the rail industry will simultaneously deliver the lowest California Tier 5 emissions objectives while providing customers a greater than 50% fuel expense reduction.

OptiFuel’s certified rail engine (EPA name KOFSG11.9400) paired with OptiFuel’s Federal Railway Administration Approval for Locomotives with compressed natural gas (CNG) Onboard Storage Systems creates a de-risked natural gas platform from which to build locomotives with power levels from 800 to 4,300 hp. The rail engine is the only U.S. EPA Rail Certified prime mover that exceeds all of California’s proposed standards for Tier 5 as currently petitioned to U.S. EPA. In addition, when used with Renewable Natural Gas (RNG), the engine will operate as a negative carbon intensive asset.

OptiFuel’s rail engine is identical to the proven ISX12N engine, certified by CARB, and used in the 6,000 natural gas-powered trucks purchased by UPS in 2020 and to be delivered by 2022. This three-year commitment and $450M investment to expanding UPS’ alternative fuel and advanced technology vehicle fleet, underscores the viability of the technology and engine to lead the trucking industry in emissions reduction. Comparatively, the U.S. freight locomotive fleet (about 39,000 units) emits an average of 8.0 g/bhp-hr of NOx as opposed to a new CNG Class 8 truck of 0.02 g/bhp-hr of NOx – a factor of 400 times. Deploying OptiFuel’s certified rail engine in the rail market will allow the railroads to meet or exceed the newest natural gas and/or electric battery Class 8 trucks in criteria and climate emissions, while saving more than 50% of current fuel costs compared to diesel.

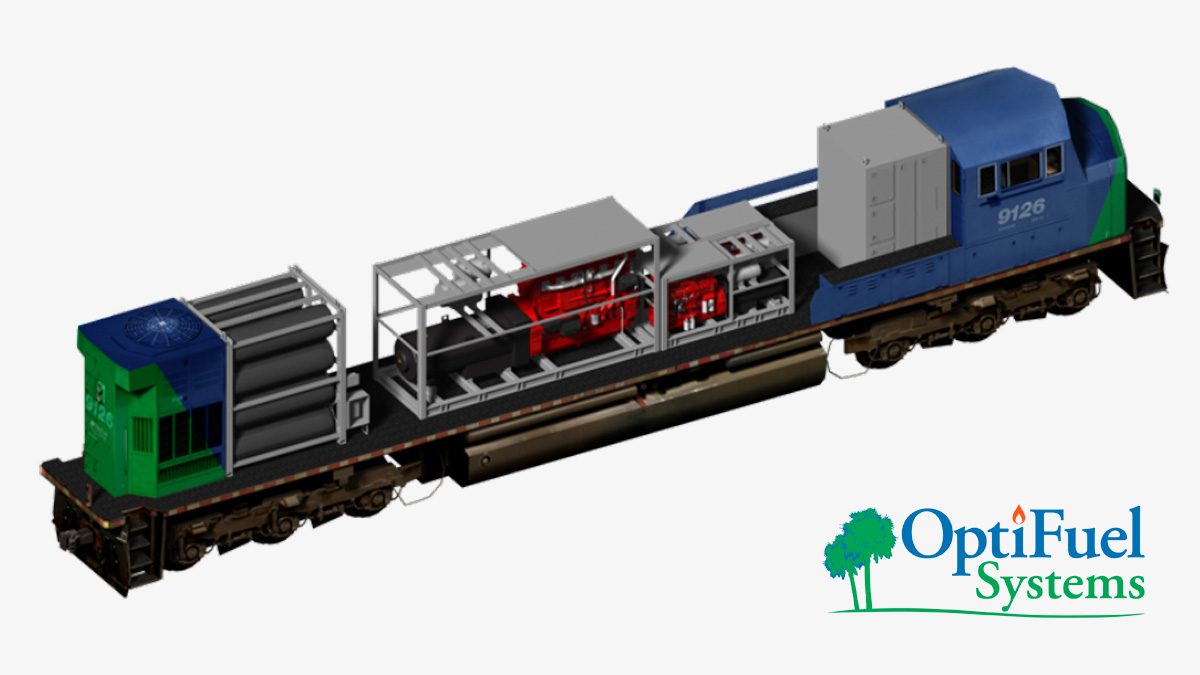

The rail engine is able to seamlessly operate on any combination of renewable and fossil natural gas in either compressed (CNG) or liquefied (LNG) form. Natural gas, and modern four stroke engine efficiency, provides the means for the lowest energy cost of any internal combustion engine currently offered in the rail market, while simultaneously delivering the lowest emissions exposures to a rail operator’s employees, surrounding communities, and customers. Requires a Longer Frame and Adding Four 400 hp 100% Zero Emission Natural Gas Engines and an Onboard CNG Module Single engine Tier 4, 2,700 hp QSK60 locomotives (NOx: 0.8 g/bhp-hr, PM: 0.01 g/bhp-hr) Affordable, 4,300 hp., NEAR ZERO emission, natural gas hybrid, line haul locomotive (NOx: 0.06 g/bhp-hr, PM: 0.00 g/bhp-hr) that can operate with Renewable Natural Gas, operating as a negative carbon intensive asset Current locomotive designs do not have to be significantly changed to adopt a natural gas solution

“All of the CNG components are designed to be modular, scalable, reliable and affordable for use in a locomotive configuration,” said Scott Myers, President of OFS. “In addition, over the next 6 to 18 months, OptiFuel will be expanding its line of EPA certified Tier 5 locomotives for the freight and passenger rail market with models from 800 hp to 4,300 hp. The engines will support multiple locomotive configurations and different modular onboard CNG storage sizes. We expect that the incremental cost to repower older locomotives and/or build new locomotives using CNG will be similar to diesel due to proven results of the OptiFuel’s Indiana Harbor Belt (IHB) CNG program. The cost of the CNG per Diesel Equivalent Gallon (DGE) will be between $0.80 to $1.25. The fuel savings, increased safety, lower risk, and cleaner emissions will make operational and financial sense to all freight and passenger railroads. Additionally, the ability to lease locomotives with an integrated CNG refueling program will create true turnkey solutions.” Mr. Myers added, “For line-haul locomotives, OptiFuel is also well along with the design of a range-extending CNG tender, in both powered and unpowered configurations, that conforms to the recently released Association of American Railroads tender standard. The powered tender will provide another 1,600 hp for a combined locomotive and tender consist of a total of 5,900 hp, natural gas substitution rate of over 90%, NOx emissions of 0.03 g/bhp-gr, and a range up to 2,500 miles before refueling. A scaled-up version of the CNG refueling station used at IHB railroad allows the tender to refuel in 60 minutes from an existing nearby CNG pipeline.”

About OptiFuel Systems:

OptiFuel Systems is a systems solution integrator providing zero emission products and services in the hard-to-abate transportation and industrial markets. OptiFuel Systems brings modernization to heavy-duty transportation, ushering in the transition from diesel power to zero-emission power with available, affordable equipment and turnkey delivery solutions that minimize disruptions to operations. OptiFuel’s innovative technology is low-risk, modular, and has flexible fuel options consisting of affordable renewable natural gas (RNG) and hydrogen fuels. Learn more ›

Contact:

Scott D. Myers, OptiFuel Systems LLC – (339) 222-7575, scott.myers@optifuelsystems.com